Written by Bryan Bastow, Brewer & Quality Control Manager

Sour beers seem to produce two extreme opinions, they are either loved or hated passionately. As professional brewers, we expel great effort and focus extensively on ensuring our beer is a clean stable product, free of any off flavors or microbiological contamination. We do anything we possibly can to prevent our beer from being spoiled, ruined, or degraded by unwanted organisms such as wild yeast or lactic acid producing bacteria. But in all honesty avoiding such microbes doesn’t always hold true for all the beers we make. As drinkers of Perrin might know, we really like to make sour beers. Sour beers are produced using either wild yeast, bacteria, or a mixture of the two. That means that the very same microorganisms that would be considered a terrible contamination in most of our beers, are also used to ferment and create the great sour beers we love. I have always found the irony of this situation slightly entertaining and I believe it is an excellent example of how varied and expansive beer styles can be from one another. It’s an interesting concept to look at these microbes as a contamination and problem in normal beer production, and then use them as a tool and necessity in sour brewing.

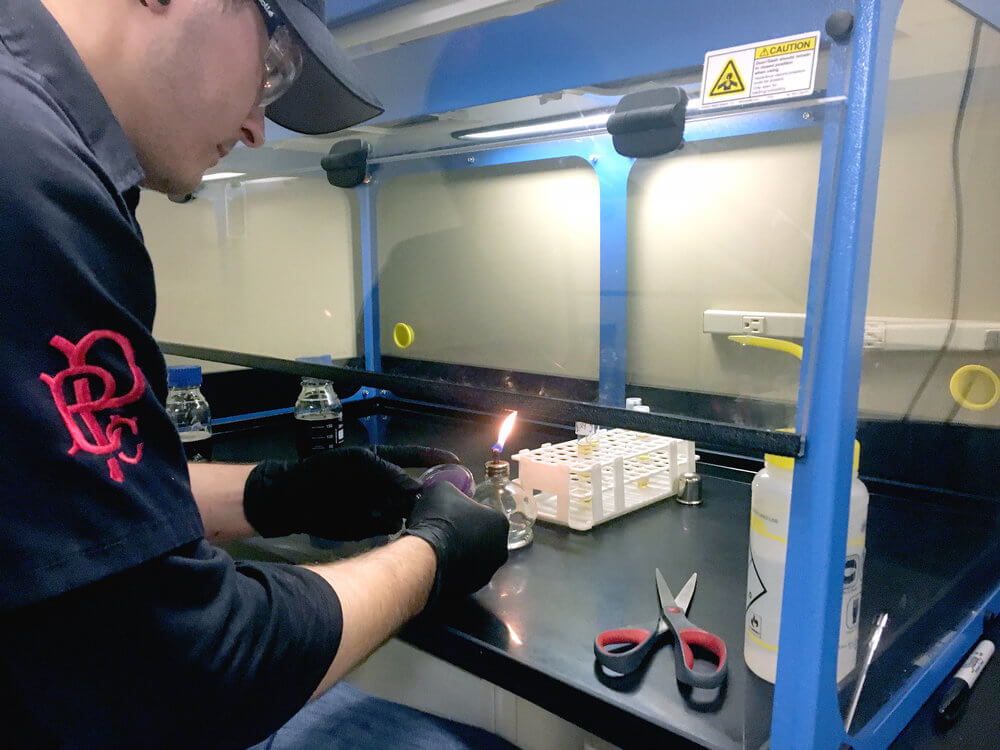

Even more intriguing is that I’m truly in the cross roads of this double-sided mindset. As the QC/Lab manager at Perrin I’m personally in charge of ensuring that all our flagship beers are free of any microbial contamination. This is accomplished through extensive microbiological testing at several stages throughout the brewing process. On one end, our production team works tirelessly to keep wild yeast and bacteria out of our beer at all costs. On the other end of the spectrum, I love being a part of making sour beers and using these microbes to produce acidic, mouth-puckering, delicious sours. Making both high quality clean beer and sour beer requires a great deal of knowledge and skill to do so. Although they may differ greatly regarding ingredients, fermentation, and the aging process we try to make sure both are held up to the same high standard of quality. Brewing sour beer is really a different world, and I love being on both sides of that fence getting to experience brewing a wide range of beers at Perrin.

Most beer, including our mainstay, seasonal, and flagship beers are fermented using either an ale yeast strain (Saccharomyces cerevisiae) or lager strain (Saccharomyces pastorianus, carlsbergensis). These yeast species have been selected and cultured over hundreds of years to perform fermentation and create flavor profiles in a very consistent and predictable manner. These “culture” yeast strains, used in the vast majority of beer production, are often referred to as “clean beers”. They are fermented using a single yeast culture or strain and any other microbe in the beer would be unwanted and considered a contamination. So…. if there is “clean beer” there must be the opposite or “unclean” beer. You guessed it; that would be sour beer. Producing sour beer is a totally different mindset revolving around unique fermentation and maturation processes. It can be made using a large array of wild yeast and/or bacteria strains. There can be one or several strains blended together depending on the desired flavor profile the brewer is looking to achieve. These mixed cultures in sour beers are ironically the exact organisms that would be a nightmare if found in our normal production brews. Although sour beers contain wild yeast and bacterial strains, that doesn’t mean any random microbe can be allowed to grow in the beer. These beers are still produced using a pure culture strain(s) that creates very specific flavors. When brewers design a new beer or recipe they envision a certain overall flavor profile, with specific characteristics and attributes. From there they assemble the exact ingredients and brewing procedures that will create the beer’s qualities precisely as they intended. When making sour beer the brewer intentionally inoculates the beer with a bacteria strain to produce a desired flavor. Any microbe that is present in the beer and wasn’t intended to be by the brewer is concerned a problem. Such organisms can create off flavors or a flavor profile different from what was planned. Therefore, sour beer can still have a contamination issue if there is any organism present besides the originally intended culture strains.

Although from a micro stand point sour beer differs greatly, all Perrin beer follows the same general outline and quality standards. The single cell organisms present will perform the fermentation process in which the sugars are broken down and converted to produce ethanol, CO2, and many other by products. There are many by-product compounds created by the yeast during fermentation. Some of these by-product chemicals have very distinct flavors and descriptors, and they can contribute strong flavor characteristics in the final product. Therefore, some yeast strains will help determine the final flavor profile of the beer, which is appropriate for many styles. The most commonly used culture yeast (such as our house yeast) is relatively neutral, which means it doesn’t produce high levels of these fermentation by-products. This means that our house Saccharomyces yeast does not greatly determine the beer’s main flavor characteristics, where as other strains may.

Wild yeast and bacteria used in beer production contributes greatly to the beer’s flavor profile. Wild yeast strains are known for making funky, spicy, horsey, peppery, and fruity flavors that are very distinct and unique. The bacteria used in making sour beers, such as Lactobacillus or Pediococcus produce acid. These bacteria contribute a great deal of flavor, most noticeably being the intense tart, sharp, and acidic aspects. Good sour beers having a range of acids at varying levels creating a well-balanced and layered acidity that is easy and pleasant to drink. Lactic acid bacteria also take much longer to ferment than cultured ale yeast. It could take months to over a year to fully complete fermentation and finish the beer’s profile. For these reasons a mixture of bacterial strains is sometimes the way to go, as different bacteria can create different levels of acids and flavors over time.

Despite the many differences between clean and sour fermented beer, they also have some similarities as well. All beer made at Perrin undergoes extensive testing and evaluation to insure no unwanted microbes are present and no off flavors have been produced. Despite how it may seem, sour brewing at Perrin is actually very tightly controlled and monitored to produce specific acid levels, flavors, and aroma. Both clean and sour fermented products are subjected to analytical, sensory, and microbiological testing. I believe this high standard of quality for sour beer is something that sets Perrin Brewing Co. apart from many other breweries that take a crack at making sours. I’m proud to say that our sour beers are held up to the same quality standards as all our clean fermented beers. All this testing verifies that everything goes as planned and we reach the original design of the beer. At every stage of the process we do quality checks to make sure no contamination has taken place and the flavor profile has developed as the brewer envisioned it.

Clean and sour beers are kept separate and use designated tanks, hoses, parts, etc. to avoid cross contamination. Although this is true, they both follow the same high quality standards. My position in the brewery lab makes me particularly nervous, obsessive, and probably annoying to others when it comes to having sour beer in our production brewery. Since sour beer contains organisms that can cause some serious problems with our flagship beers, they must be processed and stabilized to avoid cross contamination. Sour beer is put through a process called sterile filtration which removes all the wild yeast and bacteria used during fermentation and aging. From that point on it is very stable and will not have any problems in package during aging. If this stabilization process were not to occur there could be many problems that arise in the package product over time. Some of the issues could be re-fermentation in the bottle that causes pressure to build, creating bottle bombs or gushing beer. The beer could also turn “sour” in a very bad way that can be noticed by a vinegar flavor stemming from acetic acid production by the un-removed microbes. Sterile filtration or pasteurization of sour beer insures that it is stable and will be good to drink for a very long time. Considering the huge amount of work and effort put into making sour beers it is only right to finish the beer properly and make sure no issues can occur in package, resulting in wasted beer.

All in all, the duality of making clean and sour beers is one of my favorite aspects of brewing. Both styles require specific knowledge and care to produce well, although the process for each differs greatly and may seem contradictory to one another. Making sour beer is much like making modern wine in my opinion. It requires blending of different aged barrels and acidity levels to achieve a precise flavor profile and overall balance. It is truly an art in of itself and I have great respect for the beer and those brewers who make world class sours. The vast difference from a light-bodied mild lager or ale to a radical sour with high acidity shows that the drastic range of beer styles is greater than any other beverage. No other alcoholic or fermented beverage has such a wide range of flavors, techniques, processes, ingredients, and styles. It is a thing of beauty and for us brewers it gives us a constant source of experimentation to expand our brewing abilities and mind set.

It’s awesome getting to do something different and interesting like making sour beers. Brewing is my biggest passion due to the fact it is ever changing and extremely diverse. When it comes to beer styles, the spectrum seems endless and is full of drastically different procedures, flavors, colors, aromas, and more. Having all these opportunities for exploration, such as sour beers, is what keeps this profession interesting and exciting. I love working at a brewery that produces such a wide range of beers and beer styles. Our day to day operations produce huge quantities of our flagship beers that make up the strong majority of our production and sales. I like to think of these beers as clean and well-balanced, made methodically to produce solid, reliable product with high quality and consistency. On the completely opposite end of that spectrum is our sour program, which slowly produces small sized batches of specialty beers. The ordered chaos that is sour beer fermentation and aging is unlike any of our production beers. There is an element of unknown and spontaneity in sours that keeps us on our toes and allows for an injection of creativity every time a new sour is released. Both ends of this spectrum are great to be involved with, and I do my best to learn and master these styles. Knowing these beers have different needs and require different environmental factors and procedures, ensures brewing will never be the same every single day. Most days will try to fine tone our mainstays beers in effort to create the highest consistency and quality possible. Then others days will consistent of taming the sour beast and listening to what the beer’s telling you. Being a brewer demands you to wear many different hats and that you have the ability to adapt and improvise. A brewery cannot produce both world class sour beer and clean beer with a single-minded view. Making sour beer is such a tangent from normal beer it requires a whole new set of skills and knowledge. As someone who loves to learn new techniques and methods, sour beer offers an entirely new rabbit hole to jump down.

I feel sour beer is really on the rise in popularity in America and we will see much more of these styles over the following years. With that change, more and more brewers will produce sour beers and play the game of clean vs. sour beer production. I know at Perrin we try to recreate or mimic traditional sour brewing techniques, characteristics, and methods while mixing in the use of modern technology and science. Putting sours through the same extensive quality testing as clean beer allows us to make a sour beer that is not only very high quality but also very consistent and reproducible, which is something not usually associated with traditional sour beer. I hope that craft beer drinkers continue to educate and expand their palates to accept and understand delicious sour styles. When done correctly, well-made sour beer products could be some of the best beers in the world. For the sake of being able to continue to make sour beer, I’m going to do my best to convince everyone that sours are truly some of the best beers on the planet. I would greatly encourage everyone to develop an appreciation and gratitude of these powerful, complex, unique, intricate, and even refined styles.